The Origin of Mountain Air

The return of Winter to the valley of the Schoharie Kill is heralded by a great reawakening. Commencing in the early fall, as mountain roads fill with leaf-peepers and the nights begin dropping into the 40s, trucks can be seen winding their way up and down the side of the Colonel’s Chair at all hours as workmen prepare networks of hoses, pipes, and nozzles. In the base lodge management eagerly watches mercury drop in the thermometer. The residents of Hunter, heeding these signs of the approaching winter, commence their annual preparations for that long but never lonely season. Snowmaking has begun.

For over half a century a small team of specialists in the town of Hunter has spent five months of every year refuting the weathermen and their forecasts. The effort is heroic, the logistics dizzying, and the end goal particularly admirable: Fun. For all the sweat and stress of the process, the grand culmination of this effort is a smiling face at the end of a ski run - and this is what has made Hunter Mountain Ski Bowl a phenomenon of winter sports in the northeast.

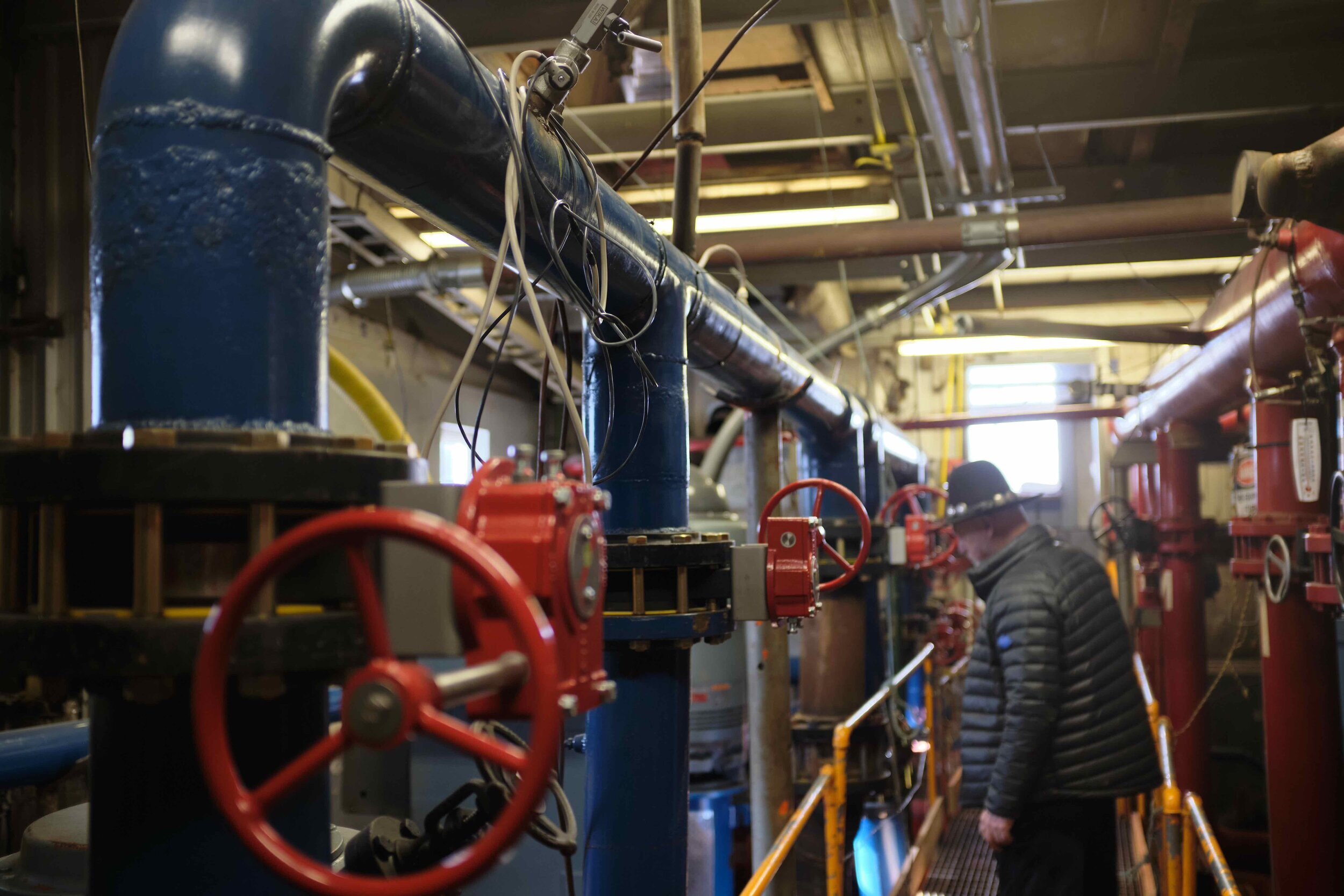

I was treated to a walkthrough of the heart of Hunter’s snowmaking operations early in 2020 by someone deeply familiar with its intricacies. The majority of the equipment used to cover the Colonel’s Chair with snow is housed in a low metal building just uphill from the base lodge and somewhat hidden by trees. Having seen the system in action I will say it is hard to avoid drawing the conclusion that the snowmaking crew has summoned something more or less alive into being using some strange alchemy and a bunch of spare parts. It is entirely a one-of-a-kind composition.

Walking from room to room in the compressor building is a jarring experience for a first-timer: the ground pulses, the air hums with an electric charge, and immense mechanical contrivances whirl away behind protective railings like zoo creatures. There is no simple way to orient yourself in this outwardly unassuming building because the machines themselves governed the construction and size of their own enclosure. It all started off modestly sized, but as Hunter Mountain grew in scale more compressors were added - each receiving a custom concrete footing after which the building was expanded to encompass the new machinery in order to protect it from the elements it was partially responsible for creating. The end result is a structure that defies architectural convention while retaining something of the organic nature of the rocky mountain upon which it is built.

The inconspicuous sheds where the snowmaking process originates.

Snowmaking itself is a tightrope walk. By finding the right balance between water temperature, air temperature, pressure, and wind an experienced snowmaker can call down Nor’easters with remarkable regularity. Just getting it wrong with one of the variables can lead to mounds of slush, fleeting icy mists, or freezing rain which can coat a ski run (and the ski lifts) in a layer of ice. In the 61 years Hunter Mountain has operated they’ve pretty much turned this stunt into a science through careful experimentation and a few hard lessons, earning the apt moniker “Snowmaking Capital of the World.”

The critical ingredients in snowmaking have always been pressure and water. You need the water to make the snow, and you need the pressure to force the water through jets or nozzles into the correct size droplets that will freeze into snowflakes. The temperature of the water can be controlled to an extent, and the temperature of the ambient air determines when you can set the system in motion. While this is relatively simple to explain on paper, its practical execution is an entirely different beast. What follows are photos and descriptions of the components that make these ingredients for manmade snow, all part of a system developed by Hunter Mountain over several decades of experimentation.

Pressure, in the case of Hunter Mountain, is delivered by immense Ingersoll Rand Compressors powered by antique Westinghouse and General Electric Synchronous Motors. These units are monstrous, and the unstoppable immensity of one of these compressors in operation harkens to the days of stationary steam engines in factories. The units that pressurize the snow guns at Hunter Mountain almost all date to the interwar period of the 1920s, 30s, and 40s - Unit 7 was actually surplussed from a Navy Shipyard after World War Two (a story in itself), and all are still in fine working order due primarily to their robust construction and relative simplicity.

While the vintage of this equipment may seem remarkable, it is important to note that these machines were the replacement for Hunter’s original and quite crude snowmaking system. When Hunter first began producing manmade snow the only equipment available was being produced for agricultural irrigation. Low-pressure above-ground aluminum pipes, gasoline water pumps, and diesel air compressors made the process almost herculean. Coordinating workmen who had to activate pumps, water lines, and adjust the air/water mix at each snow gun meant the process required lots of manpower and training. Fuel needed to be fed to all the pumps constantly, and if one pump in the line failed or stalled the whole feed line needed to be drained and reset to prevent it all from freezing up.

This all goes without saying that temperature changes over the course of a day or night of snowmaking might require almost constant adjustment of each snow gun (or “Stick”) on the mountain. As the temperatures rose and fell different ratios of water and air from each stick needed to be adjusted manually to ensure the right composition of snow was falling from the nozzle. One miscalculation and each stick on the mountain could be spewing slush onto the trails. For this reason snowmakers at Hunter walked the ski trails as long as the guns were active, keeping an eye often all night long checking that everything was behaving as it was supposed to.

In the 1980s Hunter Mountain began to add computerization to a snowmaking system that had already grown beyond the old diesel compressors and water pumps. It is this system shown in the following photos, and one that even now is slowly being phased out as technological advances have yet again changed the way Hunter’s snowmakers call down the weather.

The above compressors ensure that there is about 70-80 pounds of air at each snow gun. With the compressors taking care of generating the pressure needed for snowmaking, the next part of the recipe is supplied by a small tributary of the Schoharie Creek that trickles its way down between the peaks of the Colonel’s Chair and Hunter Mountain proper.

Unprocessed bulk snow flowing down the side of the mountain. We often mistakenly call this fluid “water.”

This small stream, the Schoharie Creek itself, Dolan’s Lake, and a separate purpose built reservoir supply a season’s worth of water for snowmaking, but it isn’t as simple as sucking the water into a pipe and blasting it out at the top of the ski trail. Since Hunter’s snowmaking system slowly became automated in the 1980s the water collected for snowmaking has had to go through an additional process prior to being sent up the mountain to make sure that it is at an optimal temperature. Think of it as passing the fluid through a radiator to chill it down to the point where it is ready to freeze. That is where this device called the Cooling Tower comes in:

Once water is chilled to the correct temperature it is piped through a manifold into a wing of the compressor building where pumps send the water uphill. A total of roughly 21 electric pumps rated at between 400-600 horsepower each are required to move water from the reservoirs, to the cooling tower, and then to the trails themselves. The main pumphouse, located under the same roof as the compressors, houses eleven such water pumps alone, and each services pipes to specific trails depending on the day’s requirements:

Just as water pumped up the mountain needs to be temperature regulated, so does the compressed air generated in those compressors we showed you earlier. The “reconditioning” process for compressed air requires equally complex systems. When air is compressed it warms - and warm air is quite literally at the top of the checklist of “things that make snow melt.” You can imagine therefore why cooling that compressed air back down might be important.

One of the outgoing air lines from Compressor 9. On several other compressors in the building these “Hot” lines are worn to a polish from years of chilled snowmakers sitting on them after a shift moving snow guns on cold winter nights. The author vouches they are quite comfortable to sit on.

What follows are some images of the room where compressed air is chilled. Because Hunter was one of the earliest snowmaking operations in the Northeast much of the system now in use is entirely custom because there was literally nobody making the components they needed. Nowhere is that “custom solutions” ethos more visible than here:

Cooled air and water finally make their way up the mountain through a myriad of pipes and hoses until they are combined in individual snow guns. The original sticks that were used to coat the mountain, which were upwards of thirty feet high, required all the air pressure the compressors developed at this point, and that 70-80 PSI pushed the water up the final stretch to the nozzle. If the snowmaker made their adjustments correctly the desired droplets formed manmade snow. Continuing refinement of techniques and equipment as relegated the “stick” to the museum - replaced by far more efficient stationary guns and smaller portable nozzles like the ones below to fill in gaps in coverage.

These newer, more efficient portable guns are a sign of the times illustrating the continuing advancements made by snowmakers in their annual effort to cover Hunter with snow.

The snowmaking operation at Hunter, in its perpetual process of refinement and advancement, will not look like this for too much longer. Smaller, more efficient compressors, advanced computer controls, and better coverage from powerful stationary snow guns have already sounded the death knell for the remarkable creation whose heart resides in the compressor building. It probably won’t be too many years before technological advancements relegate much of what you’ve seen here to the history books.

The control station, featuring tools which come in handy during long night shifts watching the monitors.

By Jonathan Palmer, Assistant Greene County Historian

Questions and comments can be directed to archivist@gchistory.org